|

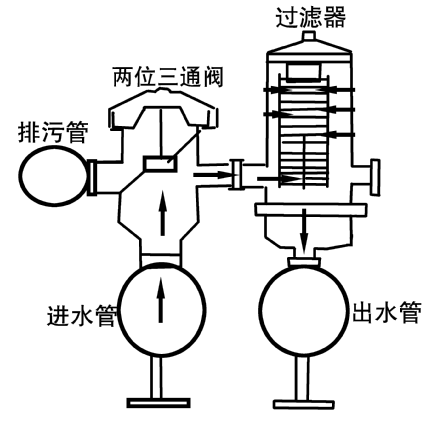

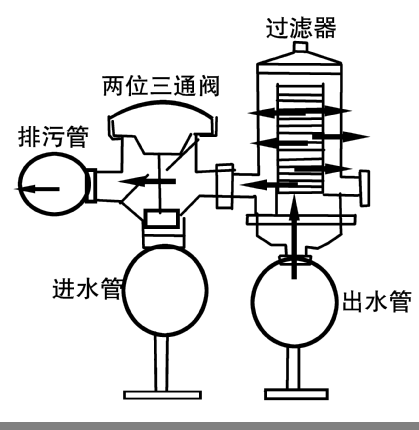

Water to be treated will flow

into two-position three-way valve from inlet

pipe. The stream controlled by valve will flow

into each filtering unit to filter. The filtered

water will flow into outlet from the channel of

filtering inner unit. The impurity absorbed by

filter will increase while the filtration is

carried out. When the difference of pressure

reaches to the set value or the set time, the

system will carry out the mode of back-purge.

First the controller will send the signal to

three-way valve related to the first filtering

unit. This valve will change the direction of

stream and close water-in and turn on sewage

draining exit. Under the reaction of pressure

the back-purge water will pass through outlet

pipe and rush into the filter to carry out wash

and the sewage will be discharged by sewage

draining exit. After the wash is finished, the

unit will recover into the filtering mode and

this system will carry out back-purge to next

unit till all unit is washed fully and the

system recovers to its filtering mode. According

to the condition of pressure at outlet pipe,

under the condition of pressure that is not

enough to support back-purge, install solenoid

valve at outlet pipe to control water flow in

order to meet the requirement of washing. (As

figure 1, figure 2) |

|

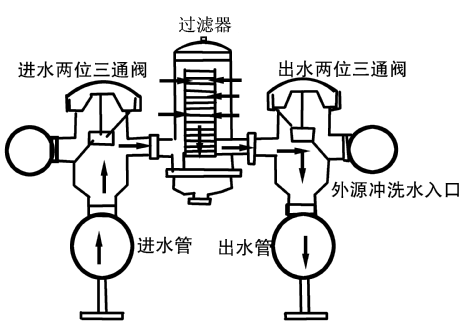

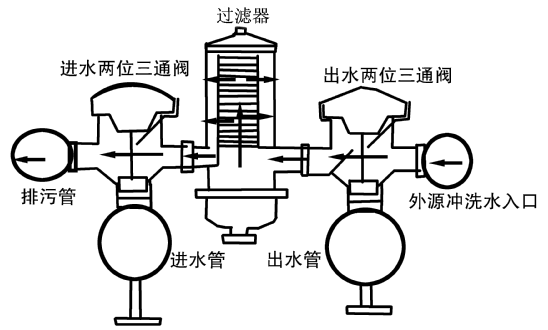

Water to be treated will flow into two-position

three-way valve from inlet pipe. The stream

controlled by valve will flow into each

filtering unit to filter. The filtered water

will flow into outlet valve from the channel of

filtering inner unit and is controlled by valve

and then flow into outlet pipe. When the

difference of pressure reaches to the set time,

the system will carry out the mode of

back-purge. First the controller will send the

signal to three-way valve related to the first

filtering unit. This valve will change the

direction of stream and flow into three-way

valve and close water-in three-way valve and

turn on sewage draining exit. Close water-out

three-way valve and turn on water-out outer

washing inlet. The back-purge water adjusted by

water-out three-way valve will flow into the

filter to carry out washing. The sewage will be

discharged by sewage draining exit. After the

wash is finished, the unit will recover into the

filtering mode and this system will carry out

back-purge to next unit till all unit is washed

fully and the system recovers to its filtering

mode. (As figure 3, figure 4) |